METAL BLANKING

Sheet metal part blanking shapes flat stock into finished profiles, most commonly through laser cutting and turret punching.

Laser cutting uses a focused beam to produce precise, complex shapes with clean edges and no tooling, making it ideal for intricate or frequently changing designs and tight tolerances. Omega’s state of the art, Japanese, 6kW fiber laser ensures the highest quality parts at the most economical prices.

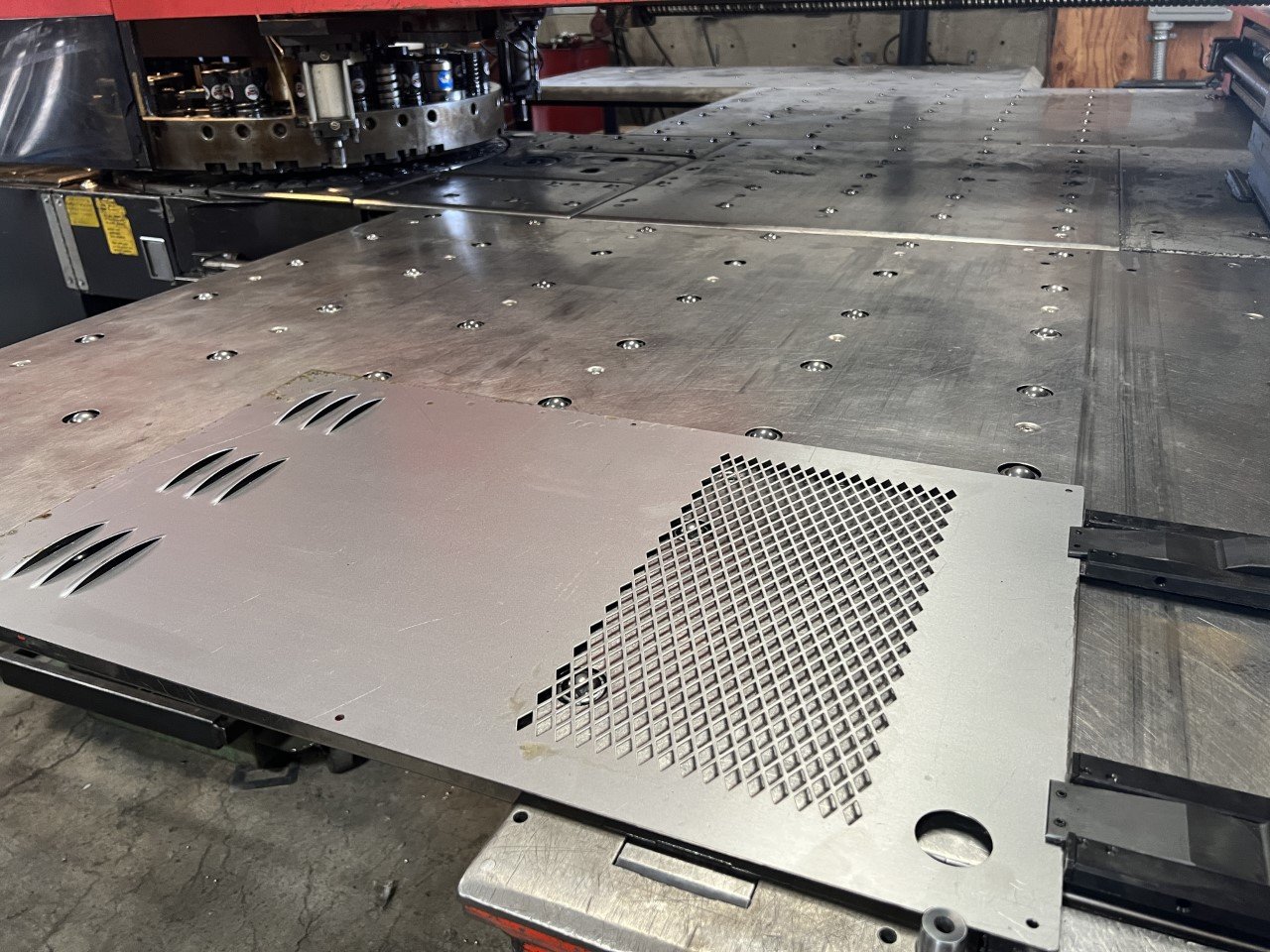

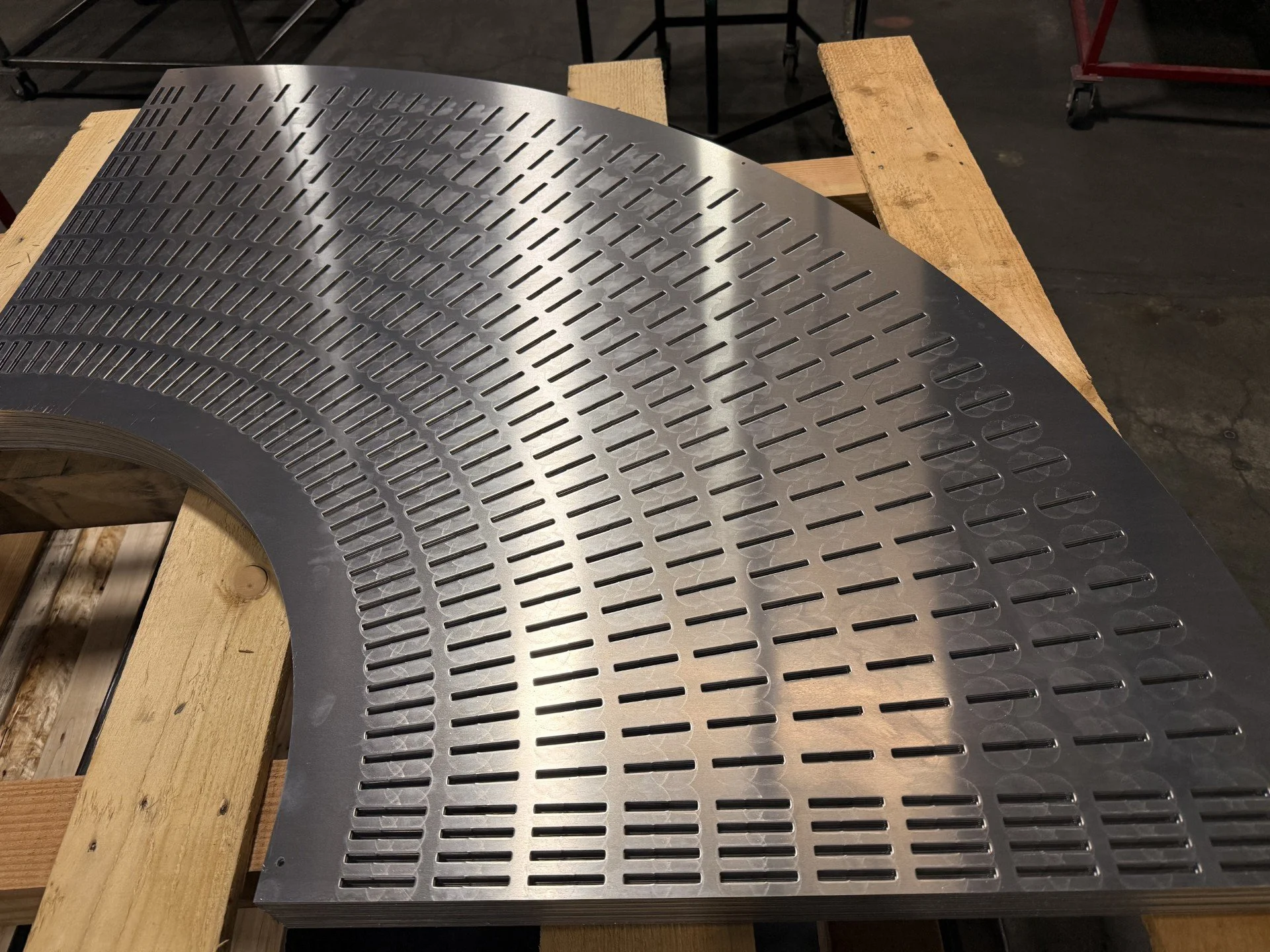

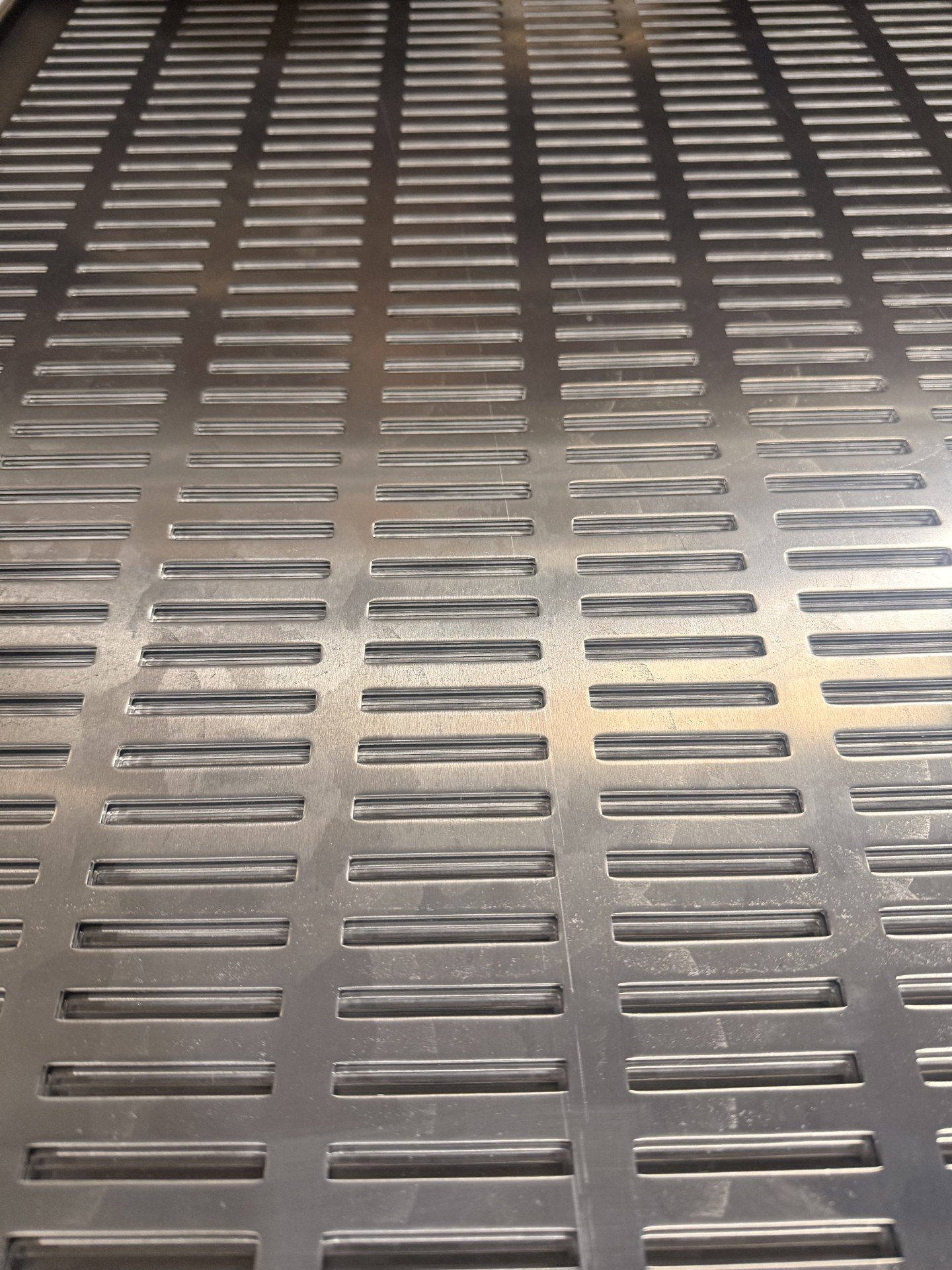

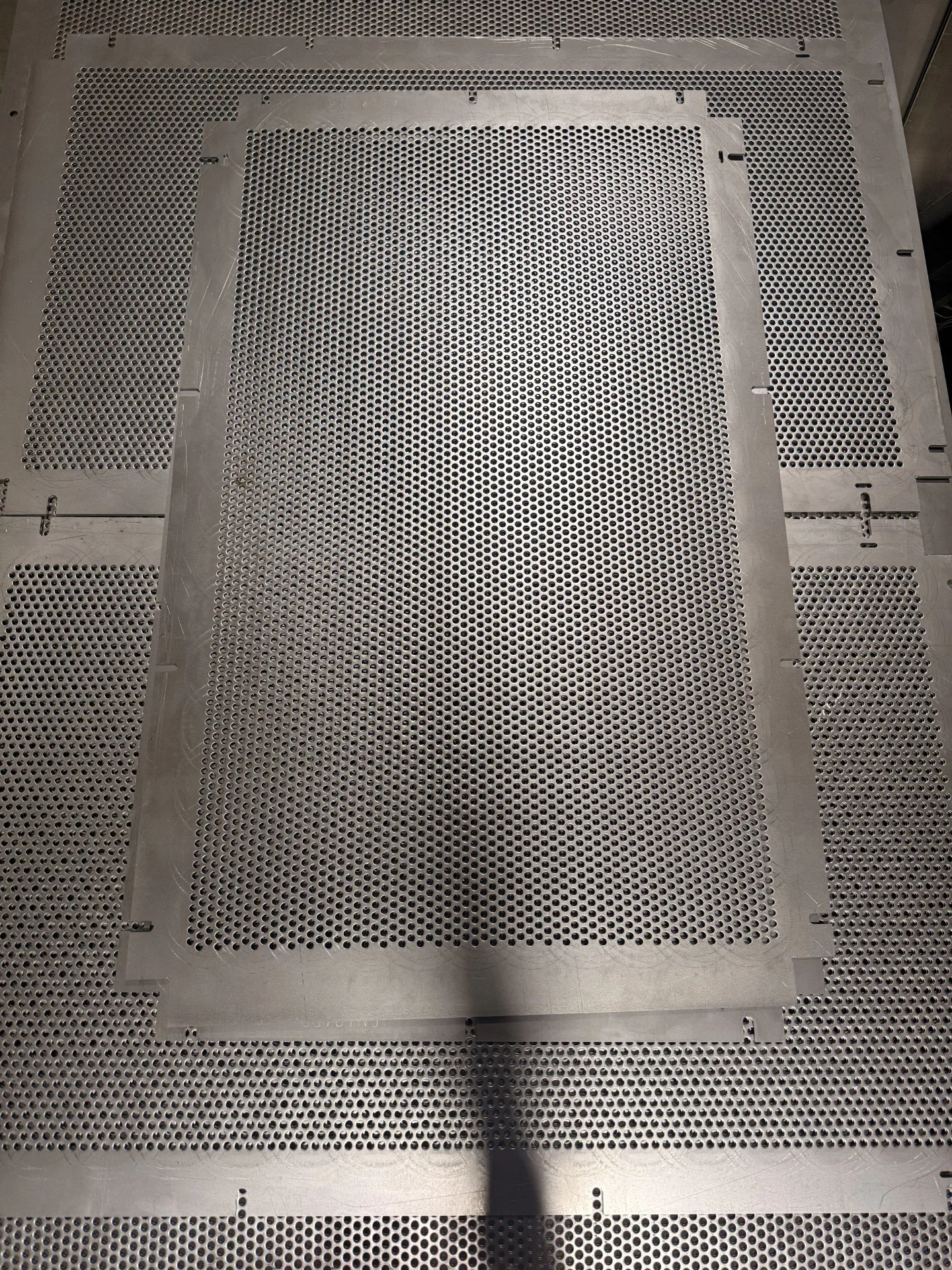

Turret punching mechanically shears material using dedicated tools, offering high speed and efficiency for similar, repeating features and high-volume production. Turret punching uniquely offers in-sheet forming such as louvers or threads. Turret punching also excels at tight, repeated patterns such at sheet metal perforating.

PROCESSES AT OMEGA PRECISION METAL

A proud Portland, Oregon sheet metal manufacturer for more than a decade.

LASER CUTTING

TURRET PUNCHING

SHEET METAL FORMING/BENDING

Press brake part forming, or bending as it’s commonly referred to, converts flat sheet metal into functional three-dimensional components through controlled bending.

Using precision-machined punches and dies, the press brake applies calculated force to create accurate angles, flanges, and channels. Modern CNC press brakes ensure repeatability, tight tolerances, and efficient setup for both simple bends and complex multi-bend parts.

This process is essential for transforming cut blanks into strong, dimensionally accurate sheet metal assemblies.

SHEET METAL PERFORATING

Sheet metal perforating with a turret punch creates consistent hole patterns and functional features through high-speed mechanical punching.

Using dedicated perforation tools, the turret punch rapidly produces uniform holes, slots, or decorative patterns with excellent repeatability. It is highly efficient for large sheets and high-volume runs, delivering precise spacing and clean features in a single setup. Our unique turret punch-laser combination allows for the creation of unique exterior and interior geometries with central perforation.

This process is ideal for applications requiring ventilation, filtration, weight reduction, or visual appeal.

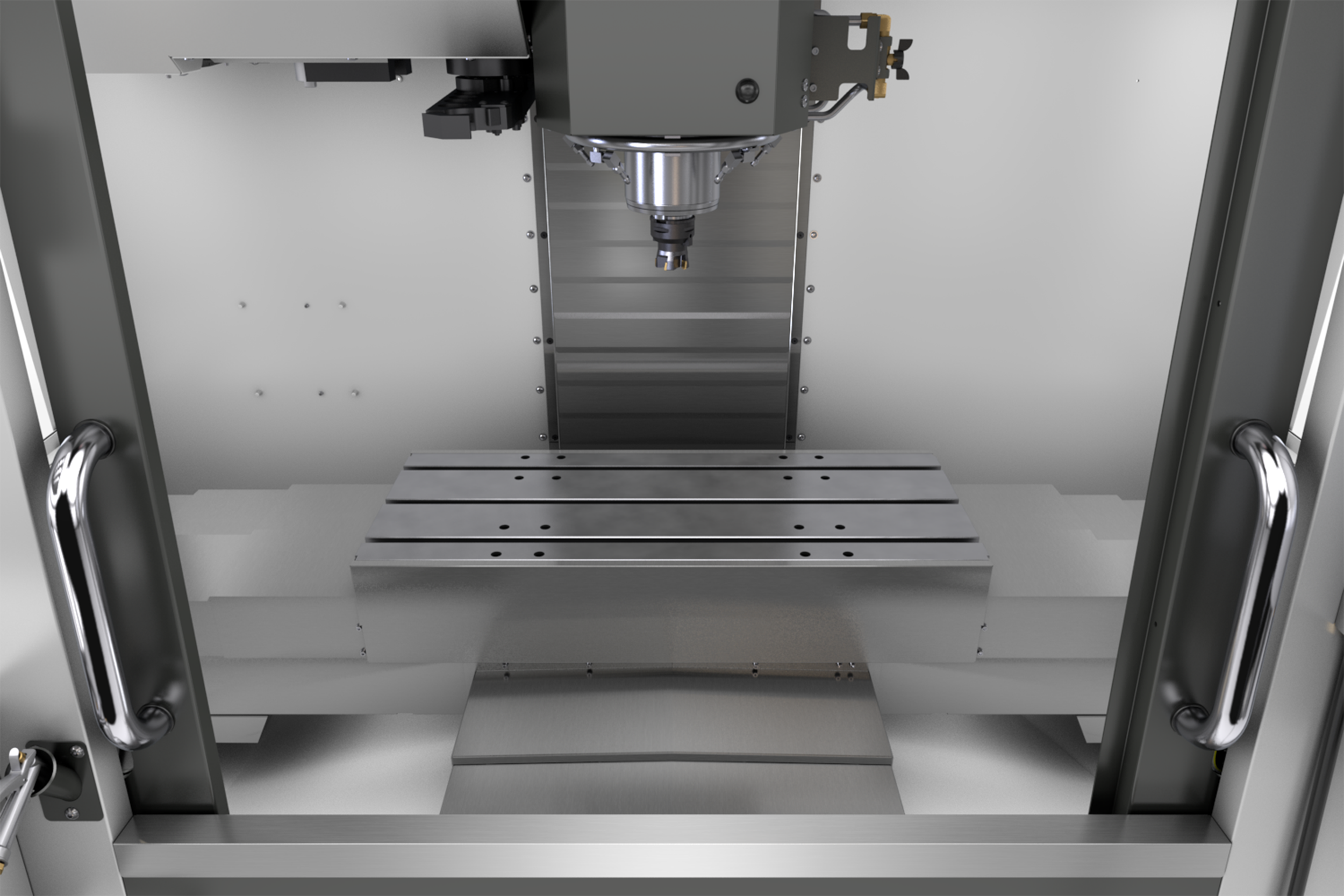

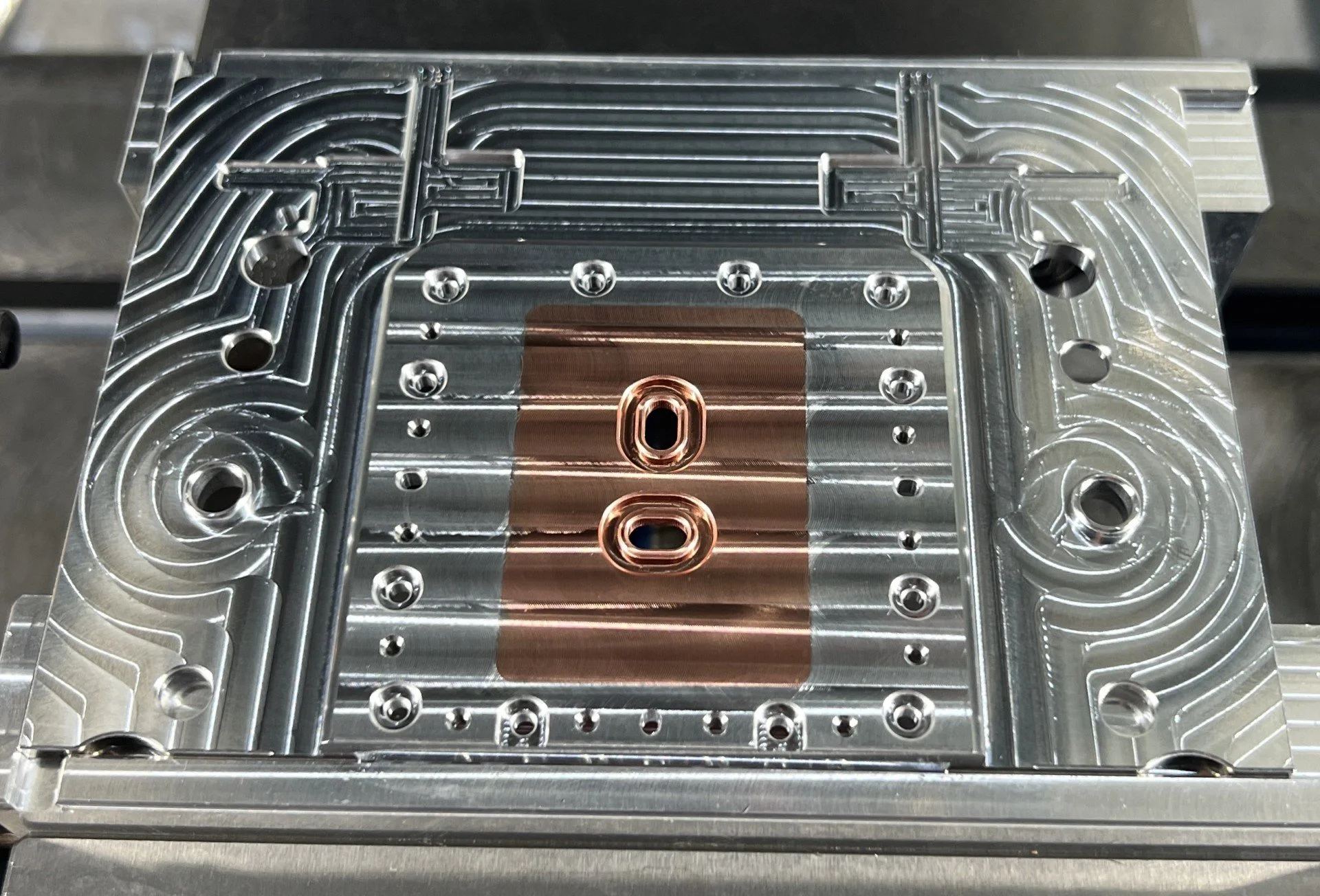

3-AXIS Vertical Machining

3-axis vertical machining precisely shapes solid material through controlled CNC milling operations.

With movement along the X, Y, and Z axes, a vertical machining center efficiently produces flat surfaces, pockets, slots, and drilled features with high accuracy and repeatability. It is well suited for prismatic parts, fixtures, and components requiring tight tolerances. Omega offers advanced processing including multi-material joining and re-machining for high-tech products.

This process delivers reliable precision and versatility for a wide range of machined parts.

WELDING AND FABRICATION

With 30+ years of experience, Omega Precision Metal are experts at all things welding and fabrication. From large scale industrial frames, aftermarket offroad accessories, safety-critical automotive brackets and everything in between, Omega is your 1-stop shop for fabricated and welded parts.

Sub-processes include precision sawing (+/- 0.010”), tube and pipe bending, mig/tig welding, tube laser cutting and more!

ASSEMBLY AND HARDWARE INSERTION

Improve functionality and decrease cost and assembly time by directly integrating hardware into your sheet metal parts.

Omega offers press fit hardware that is swaged into a base material via high pressure insertion machines. Hardware includes threaded nuts, studs, standoffs, zip tie holders, and anything else found in the PEM catalog.

SOFTWARE & ENGINEERING

Behind every high quality part at Omega Precision Metal is state of the art software and decades of engineering experience. Through the latest CAD suites and offline programming, we can simulate and verify designs before they ever hit the manufacturing floor. We specialize in design for manufacturability with full time, on staff, degreed engineers, helping customers turn complicated problems into simple, manufacturable solutions.

Omega is proud to be partnered with the following software providers.